In today’s automotive environment, state of the art diagnostic equipment is quite simply essential.

BMW work very closely with control unit manufactures to produce component ECU’s that year by year are more advanced. As such these control units no longer just drive a component, they can monitor, adjust and log faults simultaneously.

When a non-specialist garage connects their universal code reader to your vehicle they have quite literally got access to one control module (DME or DDE – this is the main engine ECU). From this process they can extract something called a P-Code which was perfectly fine back in 1996, however time has moved on and a P-Code from one ECU doesn’t even skim the surface.

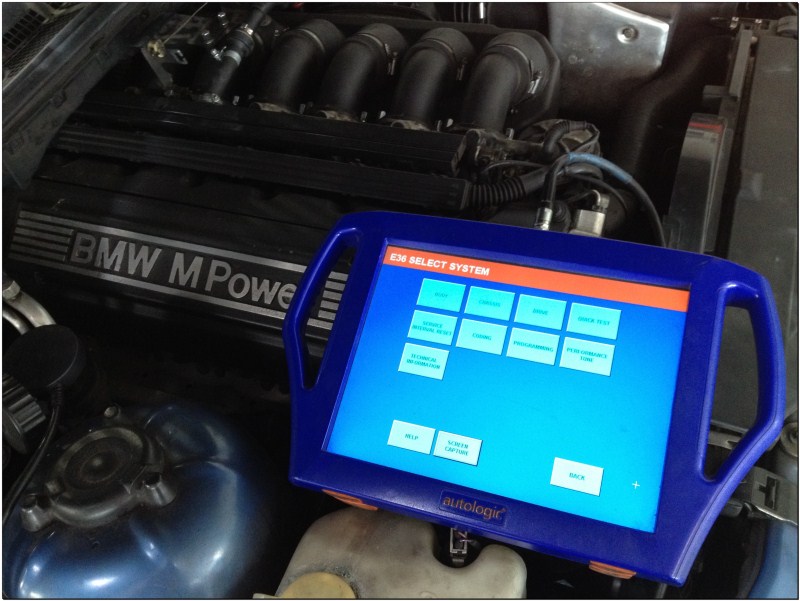

We use the BMW ISTA or the Autologic tablet systems throughout our workshop.

On a modern BMW you will have no less than 10 separate control units (even on a base model) all working behind the scenes to allow the end product to work as well as it does. This is a massive step forward in the diagnostic world as each control unit can now further monitor an individual working component and store the data locally.

Updates…

As time moves on and a vehicle has been in the open market, BMW will monitor and review software. Updates correct software scripting errors and revised software can allow a control unit to compensate for component wear or common faults. Sometimes new features can be found in updates.

Coding…

With all these extra control units comes a new diagnostic term and procedure. Every control unit in your vehicle needs to be coded. This procedure codes the chassis number, vehicle order (VO), vital vehicle data and user settings into each control unit. This process allows the vehicle to identify, recognise and use a newly fitted control unit.

Each control unit contains software that can have various settings coded (settings within a control unit can be changed). This unique process will change various settings that cannot be set or changed by the end user, ie. Region specific info / settings etc.

To advance on this further, as new technology is released like new iPod integration kits, facelift lights etc your vehicle will new coding to make the vehicle aware and work correctly with the newly fitted parts.

For more information on coding, please see our dedicated coding page.